The production is located in two production buildings and an administrative building.

The production process involved 52 pieces of equipment, of which: 35 pieces of metalworking machines equipment (7 pieces equipped with numerical software control systems), 10 pieces of welding equipment, 8 pieces of equipment for various purposes.

In the production process, the following are used: a plasma and gas-oxygen cutting machine for thermal cutting of sheet products, a strip saw for cutting rolled products of round and profile section, a sheet bending press, crank shears, welding semi-automata, drilling, turning, boring, grinding, horizontal and vertical milling machines, quenching and dispensing thermal furnaces.

Currently, the enterprise includes 10 divisions: a procurement and assembly workshop (procurement and welding section, machining section, assembly section), a production and dispatch bureau, a quality management department, a construction group, an electrical mechanical repair group, a chief designer department, a chief technologist department, a logistics and sales department, accounting, and a planning and economic bureau. 170 people work in the company.

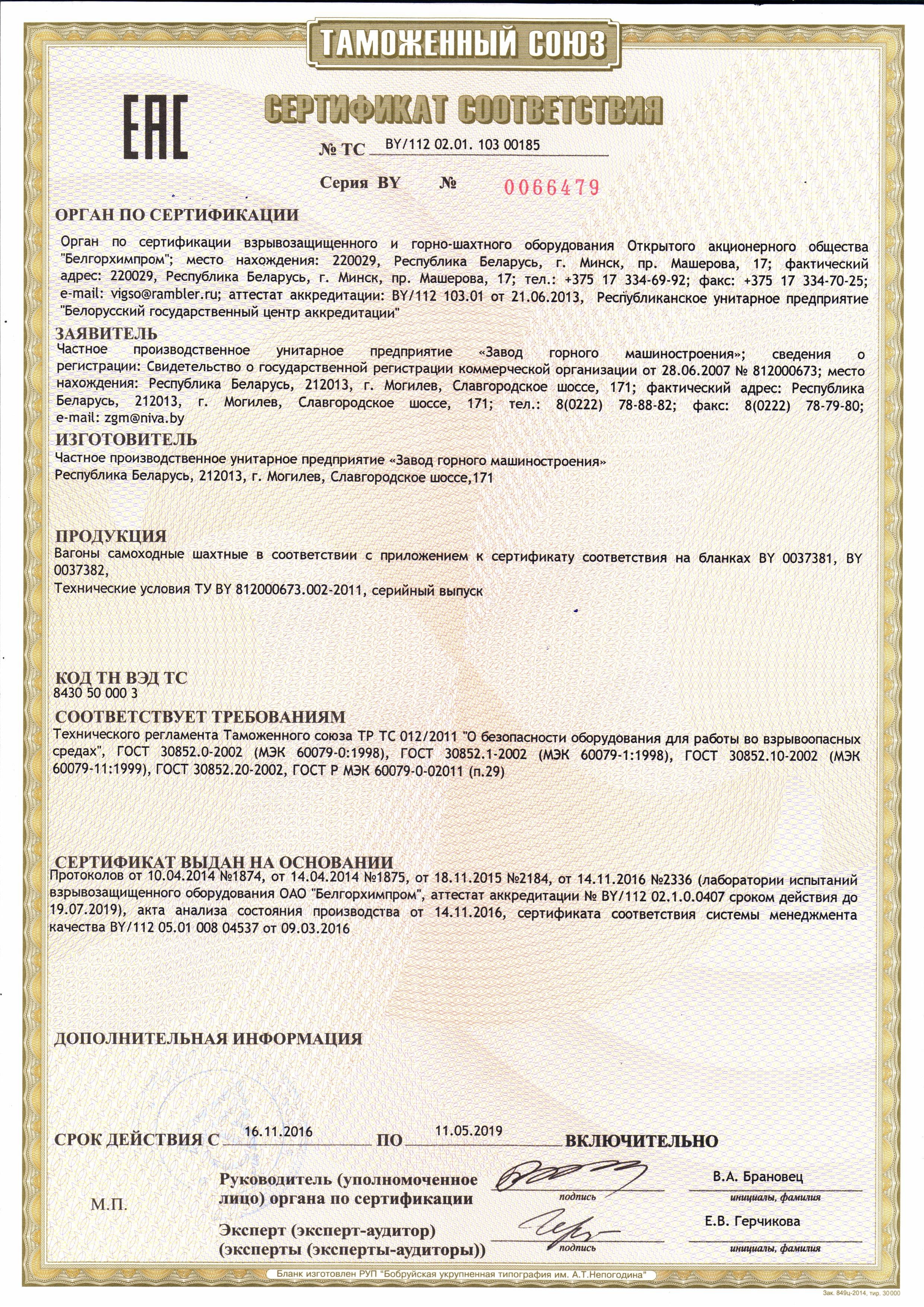

In 2015, the company's quality management system was introduced for compliance with the requirements of STB ISO 9001-2009.

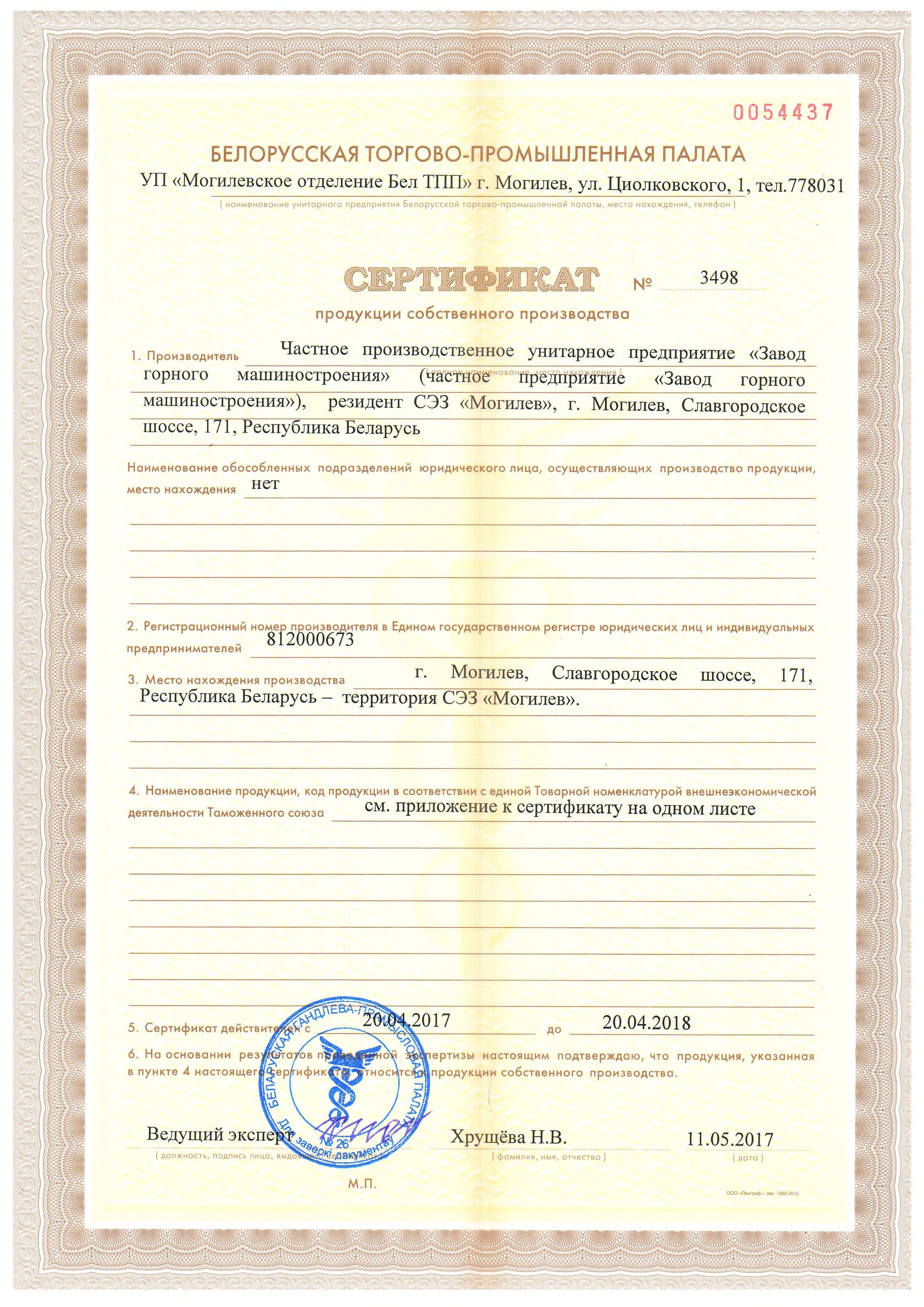

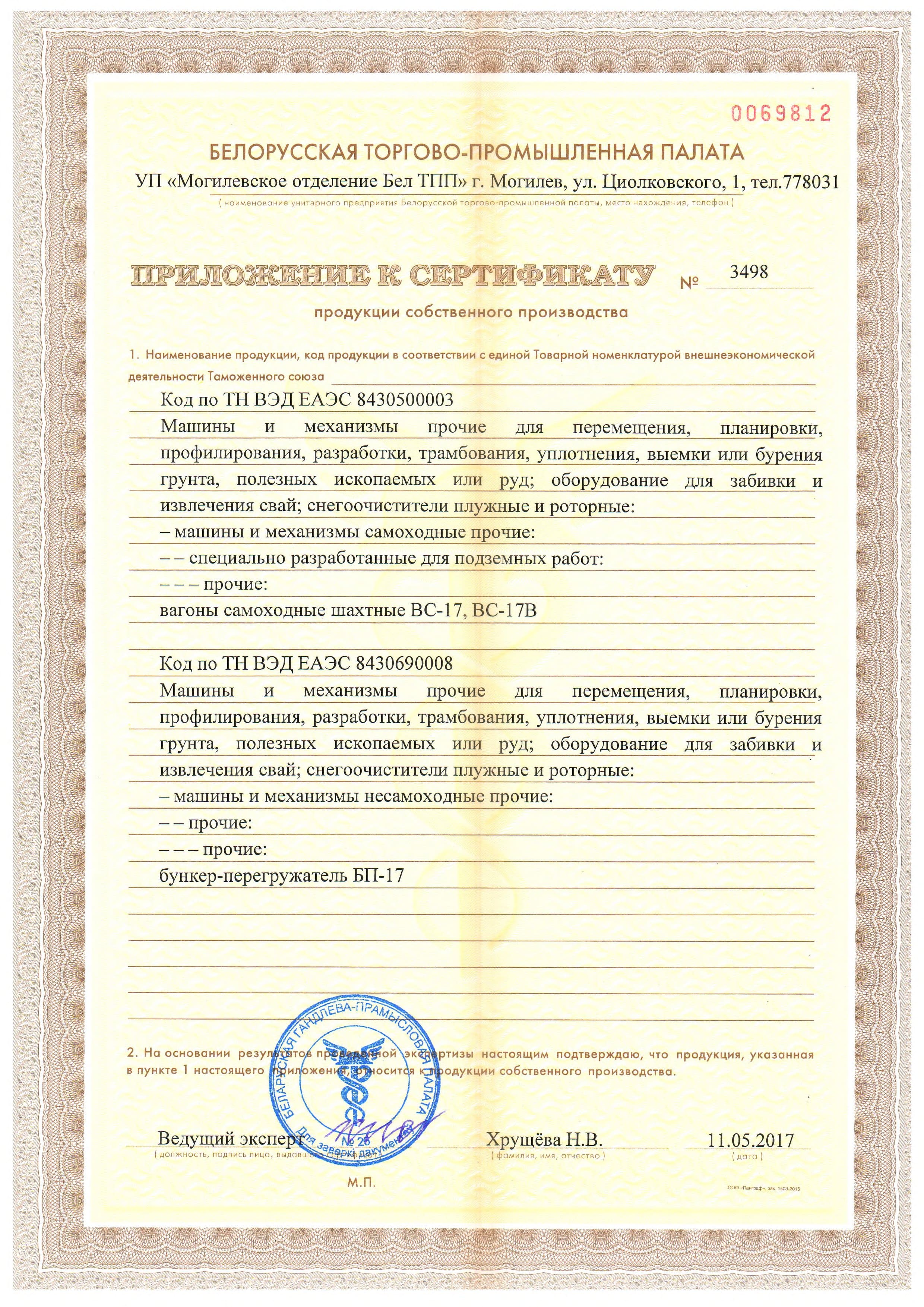

The main types of materials used at the private enterprise "Mining Engineering Plant" are ferrous and non-ferrous metals, pipes, methyses and other components, which are fully used for the production of self-propelled mine cars, bunkers and specialized equipment.

The largest share in the production structure is occupied by the production of cars of self-propelled mine of various modifications, which are the main component of the production structure, as well as spare parts for them.